We provided you the details in our latest publications of the launching of our new Soyons production unit located in Ardèche in the heart of the Aromatic and Medicinal plants' cradle devoted to extraction procedures. Today we propose to focus on the technologies we have available for producing botanical extracts.

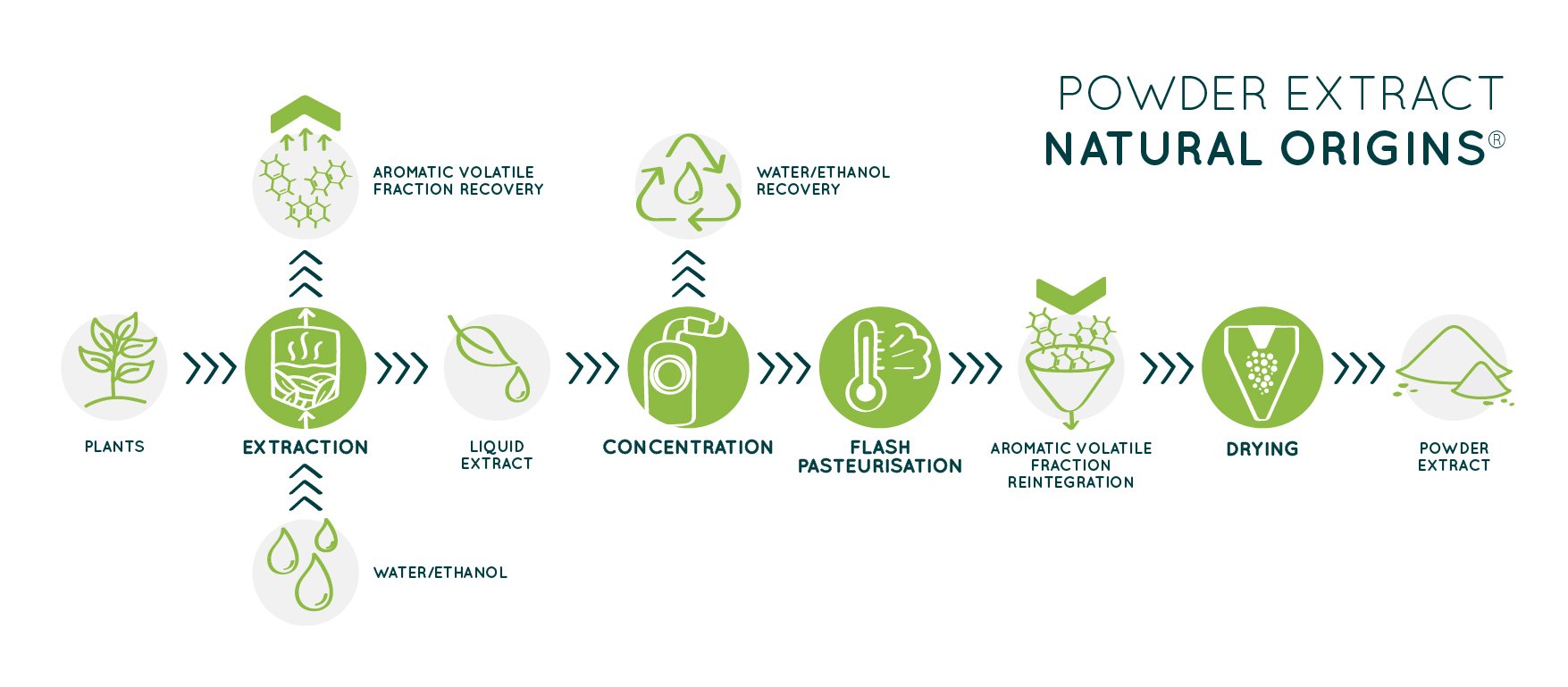

Graphic diagrams of the manufacturing process of liquid and powder extracts at Natural Origins

1. Extraction

Plants are harvested at the right moment depending on ripeness and actives contents. They are dried quickly using adapted means to preserve quality. The first processing phase involves sorting and cutting to obtain optimum granulometry for extraction. We carry out these preparation steps on our historical site next to Lyon.

These cut plants are then used for extracting using a water/ethanol mixture. Our automated percolation system makes it possible to perfectly control all the extraction parameters: contact time, percolation flow, temperature, pressure, etc.

Our tool is flexible and enables treating all parts of the plant and adapting to different defined operating conditions. The extraction process is completely automated and is extremely precise and repeatable to ensure consistent quality.

Our extraction system is likewise equipped with an aromatic plant volatile fraction recovery system. This enables isolating this substantial fraction which is generally eliminated and degraded during the traditional extraction procedures. By reincorporating this at the end of the process we can preserve the aromatic profile of the plant.

2. Concentration

The concentration step follows extraction. The objective is to concentrate the extract by recycling recuperated water and ethanol. We have a dual system evaporator equipped with a finisher which enables recuperating the concentrate while limiting losses. The concentration is carried out under pressure in order to guarantee a low temperature to preserve the actives of the extract. This equipment is fully automated and provides reliable regulating of temperature and vacuum conditions from the start to the finish of the procedure.

3. Liquid formulation

Concentrates can then be integrated into the composition of our liquid extracts. We have a tank available for these liquid extract formulations before filtering and packaging.

4. Pasteurisation

The concentrate obtained can be pasteurised using a flash type pasteurisation system. Once again we are attached to technologies which enable reducing the impact of thermal treatments. Our technology is based on injecting clean vapours to increase the temperature instantly and thus optimise the thermal treatment. This step meets all microbiology requirements.

5. Drying tower

A large part of our markets use powder extracts. We are equipped with a drying tower used to obtain these extracts from concentrated extracts. Depending on the respective recipes for each product, we add a support to standardise the extract prior to drying. The powder once it has come out of drying is mixed and sifted before being packaged.

6. Clean-in-Place (CIP)

Particular care has been taken in cleaning our production lines. We are naturally brought to handling different raw materials. Cleaning between two plants handled is essential to guaranteeing an absence of cross over contamination.

The CIP process we have conceived is adapted to all efficient cleaning processes while optimising the length of the cycle and limiting manual input. It is both a guarantee for efficiency but also for the safety of our operators.

New production capabilities at Natural Origins

Natural Origins has the annual capability of handling the extraction of 300 to 500 tons of plants at the Aromatic and Medicinal Plants' cradle in the Ardèche. This enables responding in a sustainable and eco responsible manner to the requirements of industrials throughout the nutraceutical (Life Science & Nutrition), Food & Beverage and Herbal & Teas world.

In addition to this, the company will participate in developing « Made in France » strong regional overtone plants (aromatic herbs like oregano, savory, wild thyme, thyme, medicinal plants like olive leaves, ash leaves, red vine and plants for the tea and infusions market including mint, lemon balm, amongst others).

With men and women and their unique know-how in Aromatic and Medicinal plants, small scale structures enable full traceability, guaranteeing quality. Natural Origins will likewise be able to develop the notion of terroir which is favourable to reflecting a unique brand for its clients (original acts, top notch local ORGANIC product range).

This will enable standing out with a marketing supply chain while securing an ethical and transparent procurement supply chain.

Need to create tailor-made solutions? Feel free to contact us via our Botanical Studio®.

Marc Roller, PhD

CEO & Partner Natural Origins - Head of Innovation

Leave a comment